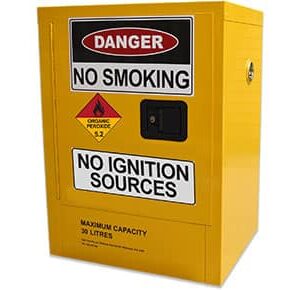

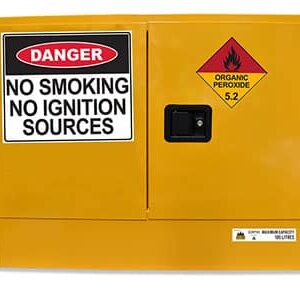

Indoor Organic Peroxides Cabinet

AS2714-2008 places restrictions on storage quantities of organic peroxides indoors. The maximum limit for storing Class 5.2 organic peroxides within an indoor safety cabinet is 100L. Accordingly, the three sizes of safety cabinet available for class 5.2 organic peroxides are 30L, 60L and 100L capacity.

Organic peroxide safety cabinets feature self-closing door with pressure release catches, double wall construction with 40mm thermal barrier and vent ports with integral flash arrestors fitted on each side.

Search Products:

Categories:

Description

Organic peroxides are oxidising agents and are relatively unstable by nature. Oxidising agents are non-combustible on their own, but the oxidation process can produce heat, fires, and gas. Oxidising agents can provide oxygen that is needed to sustain combustion. However, organic peroxide may combust on its own. While there is a notable difference between the two, both organic peroxides and oxidising agents should be handled with care and stored carefully.

When organic peroxide ignites, flames caused by this ignition can cause damage to your property due to the flames it will generate. Additionally, people in the vicinity of ignition may suffocate.

Further, even when no ignition occurs, organic peroxides are highly toxic and can cause irritation to the skin, eyes, and the mucous membranes. You should not attempt to handle organic peroxide without any personal protective equipment (PPE) or risk causing bodily injuries.

Failure to store class 5.2 organic peroxides requires them to be handled and stored safely. Australian businesses using this substance are required by law to use compliant indoor storage cabinets in accordance with AS2714-2008. Also, taking into consideration the maximum limit or amount of 100 litres that can be stored in a particular indoor site at any given time.

The compliant storage and handling of organic peroxide is outlined AS2714-2008. These standards were put in place to promote a high level of safety where these dangerous goods are stored or handled.

Severe chemical reactions caused by organic peroxides can be avoided by using safe and compliant organic peroxide cabinets that adhere to Australian Standards.

Features

Constructions: WSSA Indoor Organic Peroxide Cabinets come in 30, 60, and 100 litre capacities are All-Australian Made and built for Australian conditions. All our Indoor Organic Peroxide Cabinets meet and fully comply with AS2714-2008 – The storage and handling of organic peroxides.

And also to comply with stringent Australian Standards, safety and warning signage are also put in place.

1. Self-Closing Doors with Adjustable Shelves for Flexible Organic Peroxide Storage

2. High-Temperature Resistant Superstructure for Safety in Organic Peroxide Storage

3. Suspended Perforated Floor and Spill Containment Sump for Safe Spill Management

4. Grounding Connector for Prevention of Static and Electrical Discharges

5. UV-Stabilized Thermosetting Powder Coat for Superior Corrosion Resistance

6. Heavy-Duty Galvanized Steel Shelves for Maximum Load Capacity

7. Self-Closing Doors with Hydraulic Release Mechanism for AS4326-2008 Compliance

8. Adjustable Feet for Stability on Uneven Surfaces

9. Corrosion-Resistant Powder-Coated Finish for Long-Term Durability

10. Compliant Indoor Organic Peroxide Storage with AS2714-2008 Quantity Limits

Brief Primer about Organic Peroxides

Plastics and rubber industries are the primary users of organic peroxides. Organic peroxides and its formulations and mixtures are used in the manufacture of a variety of plastics and construction materials.

When organic peroxide decomposes, they form byproducts that may include gases such as small hydrocarbons and carbon dioxide. Though these gases are burned off in any fire, some may be carried up in plumes of smoke due to incomplete combustion.