Indoor Flammable Solids Cabinets

Class 4 Dangerous Goods (AS5026-2012 – The storage & handling of class 4 dangerous goods)

4.1 Flammable solids

4.2 Substances liable to spontaneous combustion

4.3 Substances which in contact with water emit flammable gases (dangerous when wet)

Commonly stored class 4 dangerous goods include:

Sulphur, Matches, Activated carbon, Alkali metals, Metal powders, Sodium batteries, Aluminum phosphide

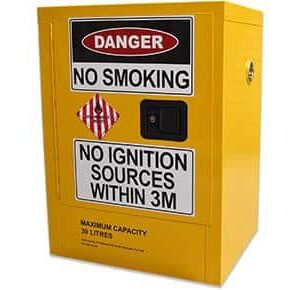

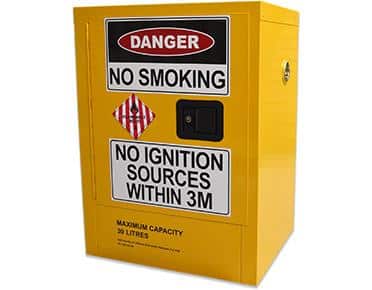

Our range of Flammable Solids Cabinets have been designed specifically for the storage of Class 4 dangerous goods. They are manufactured in Australia to ensure they meet the requirements of AS5026-2012 (The storage & handling of class 4 dangerous goods).

Features of our range of safety cabinets include; self-closing doors and, built in vents with flash arrestors, spill containment sump with drain and a yellow gloss lead-free epoxy/polyester powder-coat finish.

With sizes ranging from 30L (ideal for placing on or under work benches), to 250L capacity, we have the safety cabinets to meet your requirements.

Search Products:

Categories:

Showing all 4 results

-

30 Litre Indoor class 4 dangerous goods safety cabinet

$1,370.00 + GST Add to cart -

60 Litre Indoor class 4 dangerous goods safety cabinet

$1,425.00 + GST Add to cart -

160 Litre Indoor class 4 dangerous goods safety cabinet

$1,980.00 + GST Add to cart -

250 Litre Indoor class 4 dangerous goods safety cabinet

$2,280.00 + GST Add to cart

Description

If your business involves using, handling, generating or storing any class 4 flammable solids, you must manage the risks to health and safety associated with those solids to protect both your workers and others at the workplace.

Features

Constructions: WSSA Indoor Flammable Solids Cabinets are all made in Australia for Australian conditions. Fully compliant with AS5026-2012 — The storage and handling of class 4 dangerous goods.

The cabinets also feature adjustable feet that you can use to level the cabinet. This ensures that the cabinet would remain stable and properly levelled in moderately uneven surfaces.

And to finish the overall safety and compliant design, safety and warning signage are also in place in accordance with Australian Standards.

1. Self-Closing Doors with Adjustable Shelving for Flexible Flammable Solids Storage

2. High-Temperature Resistant Superstructure for Enhanced Safety

3. Hydraulic Self-Closing Doors Compliant with AS/NZS 5026:2012 Standards

4. Durable UV-Stabilized Powder Coating for Long-Lasting Protection

5. Grounding Connector to Prevent Static and Electrical Discharge

6. Heavy-Duty Galvanized Steel Shelves for Maximum Load Capacity

7. Three-Point Self-Latching System for Added Safety Against External Exposure

8. Suspended Perforated Floor and Spill Containment Sump for Spill Management

9. Corrosion-Resistant Powder Coat Finish for Easy Maintenance and Durability

10. Compliant Flammable Solids Cabinets as Your First Line of Defense in Fire Prevention

Brief Primer about Flammable Solids

There are three divisions that define flammable solids and substances which our cabinets are capable of handling.

Division 4.1 — Flammable solids, self-reactive substances and desensitised explosives.

These solids are readily combustible, especially under conditions of transport. They can ignite or may contribute to fire through friction. Self-reactive substances are dangerous when exposed to heat or heat sources, while desensitised explosives may explode in their pure state and not sufficiently diluted.

Division 4.2 — substances liable to spontaneous combustion.

This includes Pyrophoric and self-heating substances or solutions and mixtures of liquid and solid that are extremely dangerous and highly combustible when exposed to air. These are most liable to cause spontaneous combustion. Self-heating substances ignite when stored in large amounts and/or left for long periods of time.

Division 4.3 — substances that, on contact with water, emit flammable gases.

Division 4.3 substances earned its moniker of “Dangerous when wet.” These substances when it comes in contact with water emits flammable gasses that can potentially be explosive once exposed to air. Such fumes or gasses can easily be ignited and explode even by ordinary ignition or heat sources such as unprotected light bulbs, naked lights, and sparks. Additionally, the emitted gases may even be toxic.

Knowing the classification and division of flammable solids is important for any business handling such materials, its dangers and why it is vital to comply with safety regulations, most especially when they are being handled indoors.